Here’s how to tap the voice of the customer to create an early warning system to evaluate product development efforts, cut costs, and boost customer loyalty.

In the rapid pace of today’s product development world, companies are constantly trying to update existing products or release new ones to better meet the needs of their customers. But as each new release is designed to increase customer happiness with the product, inevitably things go wrong sometimes, resulting in dissatisfaction.

Depending on the severity of the problem, product issues can either result in a minor inconvenience for your customers or, in a worst-case scenario, a full-blown class action lawsuit against your company. Developing an early warning system based on numerous customer signals can make the difference between thousands and millions of dollars of costs incurred due to product issues, not to mention all of the negative customer impacts your company can avoid by acting sooner.

Why Product Quality and Reliability Matters

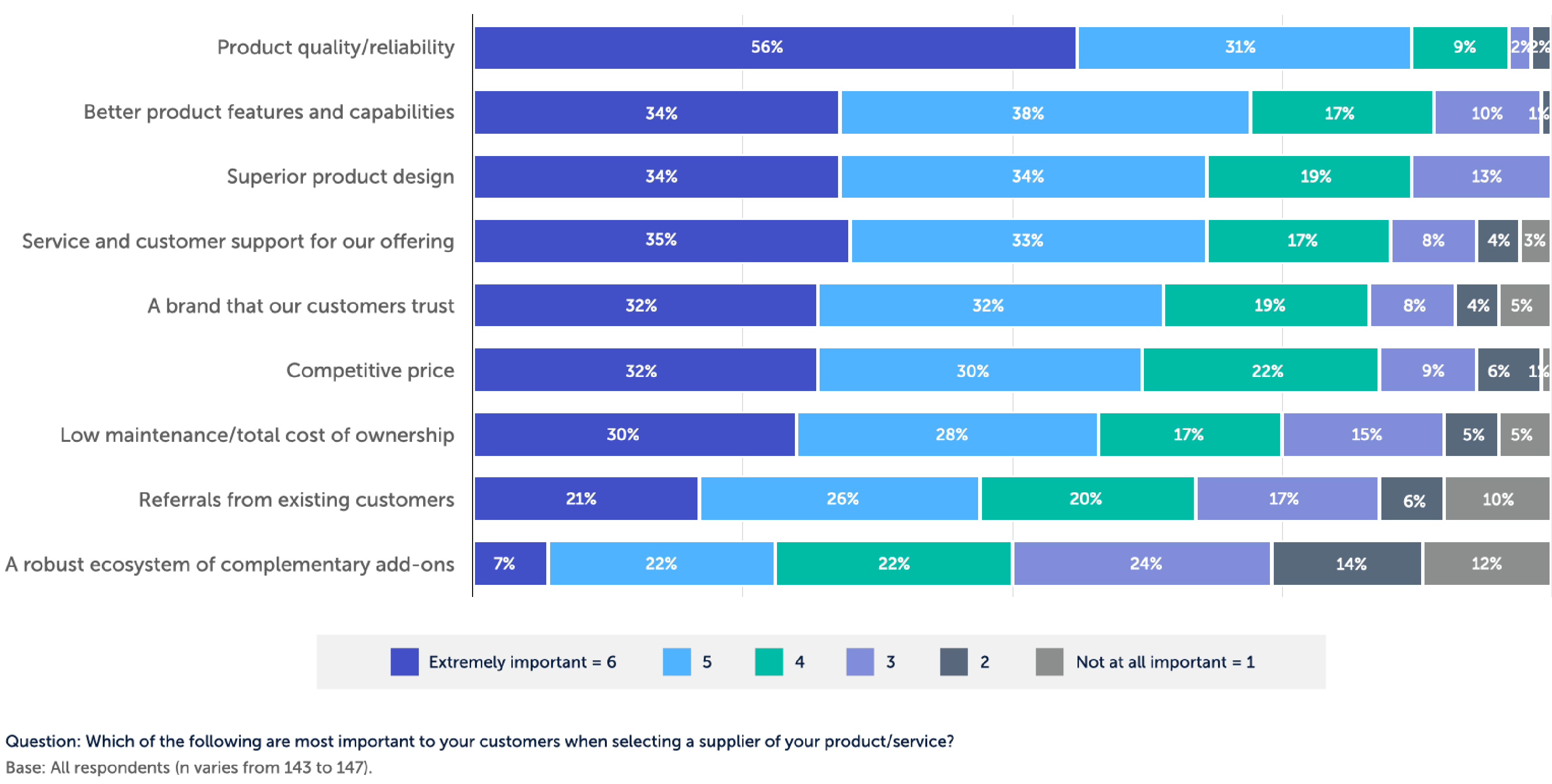

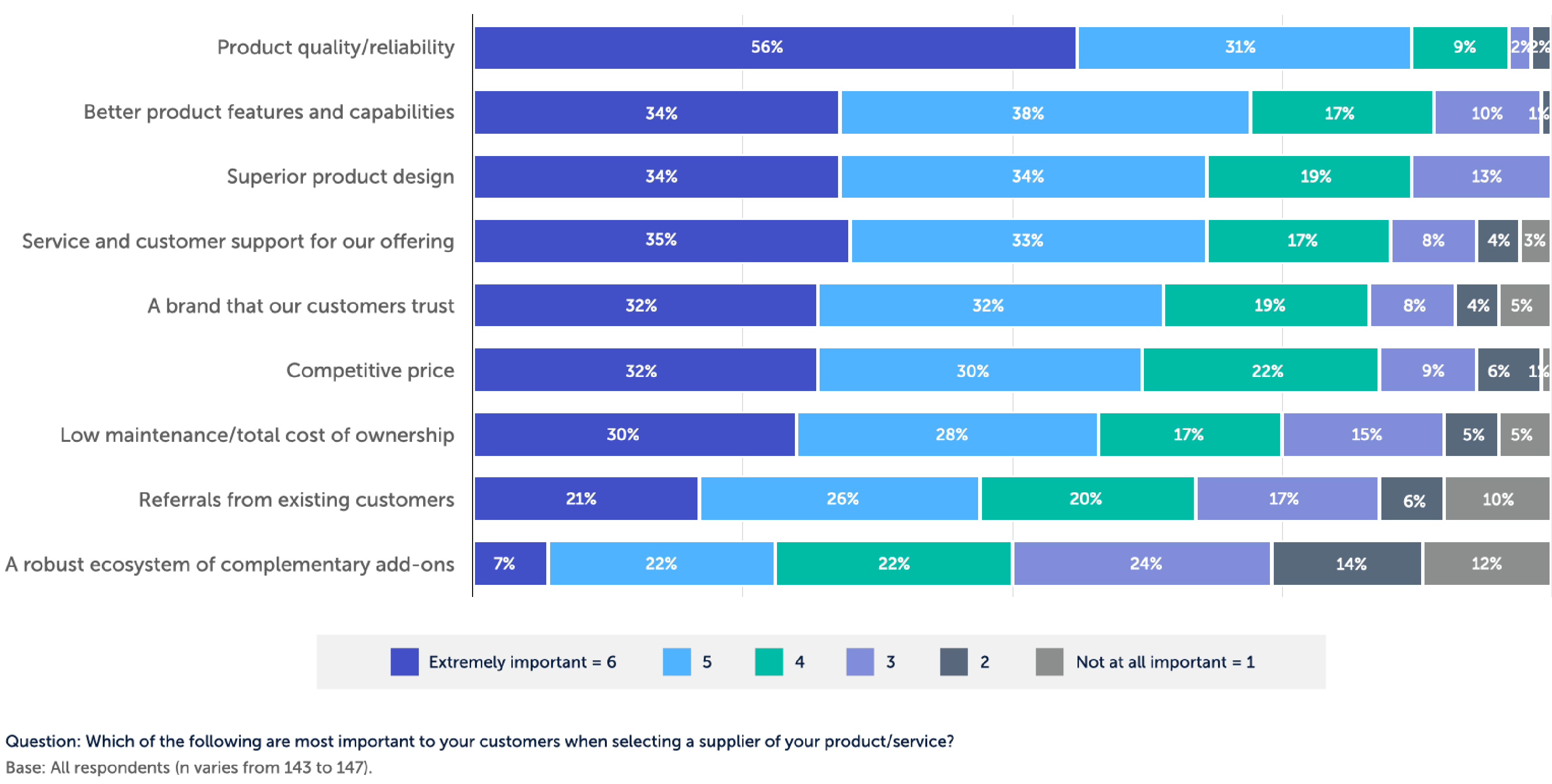

Product quality and reliability are typically the top drivers for why customers choose to buy from companies. In fact, in a study of 147 product companies conducted by Industry Week in conjunction with Medallia, 87% of product organizations overwhelmingly feel that product quality and reliability are the primary reasons that their customers buy from them.

This feedback tells us that when quality and reliability issues occur, a company may not only contend with high costs to support and repair those product issues, but it is also likely that customers will choose another company the next time they purchase.

Quality Early Warning System Detection

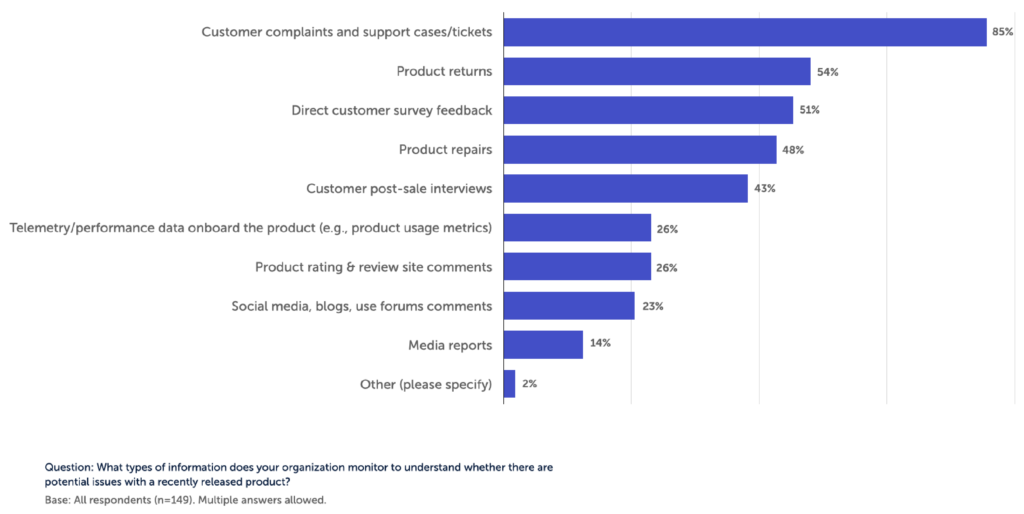

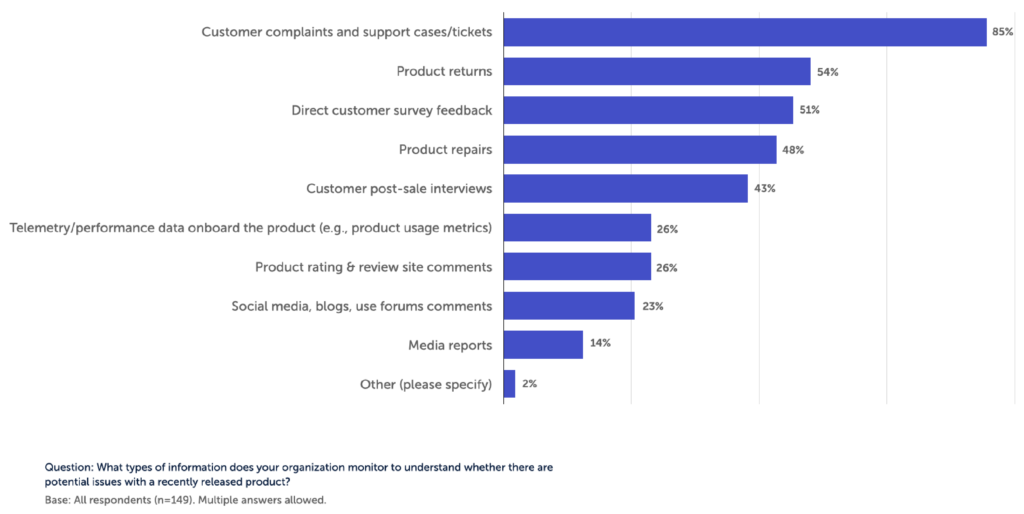

In this same study, when these companies were asked how they monitor and detect customer issues with recent product releases, the majority indicated that they leverage backward-looking signals such as customer support cases, product repairs, and returns.

Of course, support cases, repairs, and returns are critical indicators of a product’s health and should be included in every quality monitoring system. But unfortunately, they are also indications of a serious failure. A customer who encountered a product issue had no recourse other than to contact support, ship the product back for repair, or worse — return the product for a refund.

It is the general nature of product development that product defects do occur as we try to maximize the price, feature, or value curve for our customers. Product organizations rightfully sacrifice perfection for speed to market, value, and cost efficiency, resulting in an acceptable rate of defects.

Reduce Negative Impacts and Costs

It is not economically feasible to eliminate all defects, however, it is possible to detect them sooner, drastically reducing negative customer impacts, product support contacts, and repair costs. Early detection can be achieved by aggregating and automating insight creation from numerous customer signals. The longer it takes to detect issues, the greater the impact on customers and cost to the business.

Cost for a specific defect could be represented by this equation:

Total Cost of Incident = [(Cost of Support Engagement) + (Repair Cost) + (Customer Refund) + (Negative Impact on Future Customer Purchases) + (Negative Impact on Customer Referrals)] X (# of Customers Affected Per Day) X (# Days)

By reducing the last factor (# Days) in this equation, an early warning system can have a tremendous impact on the overall cost implications for a company. In fact, the longer an issue persists in the field, the more likely the cost grows exponentially and spirals out of control.

A product company can create a better Quality Early Warning System (QEWS) to alert of trending issues by amplifying the amount of solicited (e.g., feedback, surveys) and unsolicited (e.g., observed performance, social media, and forum posts) customer signals to sound the alarm quicker. Every product company today has some customer feedback signals, many of which can provide early warning on customer sentiment prior to generating countless support cases.

Aggregating these early warning signals and automating the alerting function for quality professionals can result in millions of dollars of savings each year.

A faster warning system may include data from feedback, performance, and operational systems:

QEWS = (# Support Cases) + (# Repairs) + (# Returns) + (# Product Survey Detractors) + (# Negative Product Reviews) + (# Employee Proxied Interview Feedback) + (# Negative Social Media Mentions) + (# Product Telemetry Data Alarms) + (# Negative Media Reviews)

With the exception of support cases, repairs, and returns, many of these feedback signals occur before a customer begins the process of seeking assistance. Even top retailers frequently use low-performance ratings and reviews as criteria for removing products from shelves.

Fortunately, leveraging a combination of early signals can drastically reduce the number of days it takes to detect and correct product issues, resulting in lower costs, happier customers, and increased future sales.

Learn more from the experts

The right Quality Early Warning System can save your business millions of dollars while strengthening customer loyalty to your brand. Expertise in product quality improvement can dramatically improve speed to detection and resolution. Discover how you can get the competitive advantage with Medallia technology and services.